Lean Thinking and Six Sigma methodologies integrated together to manage improvement from data, realized through people

The Lean Six Sigma is a continuous improvement system, focused on 'exploring innovative models of process management, achieved by changing the paradigms of established standards and continuously challenging the company with the aim of achieving new goals.

The Lean Six Sigma combines the focus on waste elimination typical of Lean Thinking with the exploratory approach based on statistical interpretation of data characteristic of Six Sigma.

Objectives achieved:

Lean Six Sigma is a method suitable for solving complex problems, in companies that want to challenge themselves to grow in skills and effectiveness. It is applicable in all business processes: manufacturing, transactional, logistics, financial, service and support due to the significant quantity and quality of tools available:

Lean Six Sigma takes advantage of the information provided by data, framing it within its own overall behavior, using the statistical approach as a mental form to data analysis. The fundamental message of statistical thinking in Lean Six Sigma is related to the concept of process variability: from understanding process variability comes the need not to trust point data unless properly contextualized. The ability to choose the right tool in a cost-effective manner (effort commensurate with the objective) comes with attending to the tools, with experience in projects, and with using the method. Reasoning about data in overall terms and not just by their average value provides companies with an undeniable advantage.

To effectively ensure the improvement process, Lean Six Sigma follows a project-by-project approach. Each project is a unique event that must demonstrate that it brings economic benefits to the company in terms of improved operational KPIs and consequent financial results, and that it is organic with the company's strategic vision.

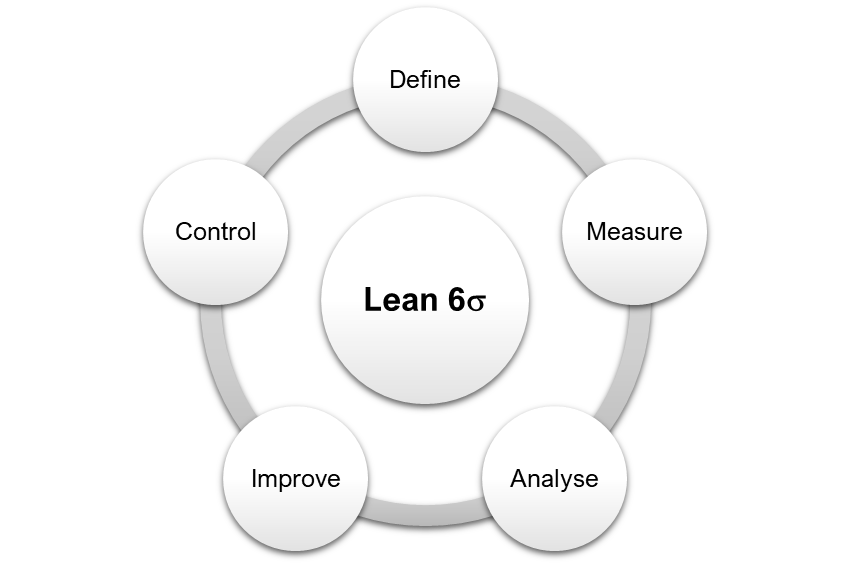

The Lean Six Sigma methodology is summarized in the project phases according to the acronym DMAIC (Define - Measure - Analyse - Improve - Control.). With the DMAIC method, the company can learn to guide projects according to the scientific method, focusing efforts on solving problems economically and efficiently.

The 5 Steps enable:

The improvement organization

One of the undisputed strengths of the Lean Six Sigma methodology is the creation of a "matrix" organizational structure dedicated to the pursuit of improvement. This structure, drawing on the high-potential resources in the company, plans to engage them for improvement projects, even in areas thematically distant from people's normal day-to-day operations.

The approach creates experts in a method, disseminating them throughout the functions to share culture and tools. These figures are identified by the color of the "belts," to indicate the level of expertise achieved in the knowledge and application of the method and tools: Lean White Belt, Lean Yellow Belt, LeanGreen Belt, Lean Black Belt, Master Black Belt.

The goal is not to build statistical specialists, but effective process optimizers with a Six Sigma mindset. Often the functionality needed to use the data in depth is available in a standard spreadsheet: it is knowledge of the tool that allows it to be used correctly, effectively and functionally for the purpose.

Structure:

La Lean Six Sigma Certification finally ensures an adequate level of theoretical knowledge, coupled with effective practical experience. In fact, to obtain a Certification, it is necessary to pass a test on the theoretical knowledge acquired and to complete (at least) one project. It is Certification that makes it possible to distinguish a project leader (Green Belt and Black Belt) from a simple expert in Statistics: the former find an operational "so" from analysis thanks to the forma mentis devoted to problem solving, while the latter stop at numbers and formal analysis.

10 days of Learning by Doing training + Tutoring to implement the company's Project Work+ Certification Day