Lean Digital Transformation and the 5G Factory | Case Study

EXOR International is an Italian company which operates globally, designs, develops and manufactures solutions HMI, control and industrial IoT that integrate the ease of use of advanced technologies.

The collaboration between Exor International and Bonfiglioli Consulting began when management set out to. To implement a new logistics-production model, with a lean perspective, in order to support and govern the growth in demand and variety demanded by the market, increase the productivity of the production site, rationalize inventory and decrease the delivery time to the end customer.

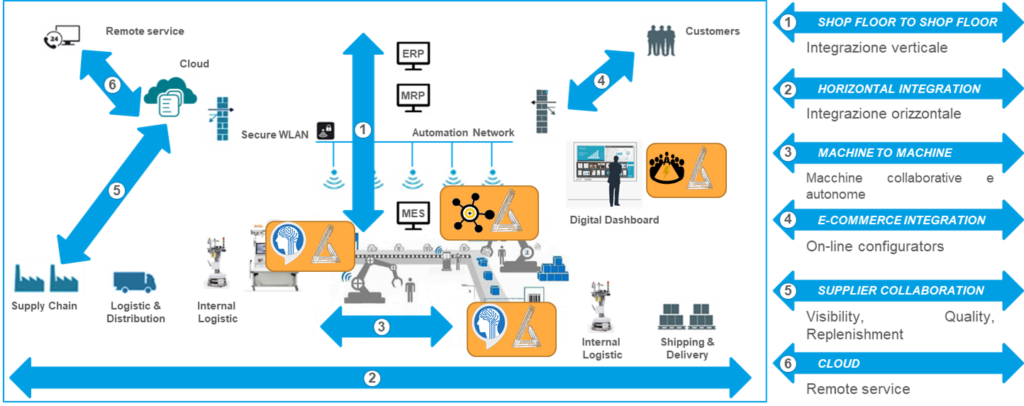

Together they worked on the creation of the first 5G FACTORY in which every part of the process is digitized to optimize processes and products through the collection and use of every piece of data and information. A project that, thanks to the widespread use of the new 5G technology within the new production site, makes it possible to accelerate the digital transformation Of enterprises.

Activities related to processing in a Lean perspective Were:

Subsequently, a series of projects were initiated to enable the digital transformation Of Exor International in collaboration with Digibelt Ltd., innovative startup of Bonfiglioli Consulting.

Process control on laser stamping equipment using sensors and an Anomaly Detection algorithm that can identify anomalies in the stamping process based on the following data from the sensors :

Drift control operation siliconing plant

Adopted Solution: use of sensors and an Anomaly Detection algorithm that can identify anomalies in the Siliconing process based on abnormal vibrations, an abnormal vibration could represent a blockage of the siliconing arm.

AOI (Automatic Optical Inspection) Project.

Target: Detect any screen anomaly (7'', 10'', 15'', 17'', 19'', 21'' TFT)

Solution Adopted: Use of pre-processing algorithms and Artificial Intelligence (Neural Networks, etc.) accelerated by specific Intel hardware (Movidius Stick), for online analysis and identification of potential defects.

Through a 4K linear digital camera, captured images are processed and compared in real time with "Good" TFT images. Any differences are highlighted as potential Anomalies.

An experienced operator, on board the machine, consults the image with evidence of the various identified defects that he can classify for statistical purposes.

Smart Factory KPI Project

Target: identification and creation of Dashboard with KPI directional e operational fed by data from the field (Corvina) in real time and identification and creation of Dashboard e Customer KPIs To create a Customer Experience.

Solution adopted: defining KPIs and building an interactive dashboard.

The goals achieved by the team were:

PRODUCTIVITY.

LEVEL OF CUSTOMER SERVICE

LEAD TIME FINISHED PRODUCT DELIVERY